Introducing biobased, biodegradable and home-compostable ‘bio-film’— a greener alternative to petroleum-based mail-wrapping solutions.

It’s no secret we need to curb our current plastic production to improve the fragile state of our environment, which is why we’ve chosen to adopt a new, more environmentally friendly mail-wrapping solution — biobased and biodegradable plastic, aka ‘bio-film’.

Biodegradable plastics — particularly those that are biobased and compostable — are a vital tool with a key role to play, today, in addressing plastic pollution. Derived from natural resources, such as sugarcane cassava and corn, BioPBS™ bio-film is compostable into biomass, carbon dioxide and water.

Why biobased and biodegradable is the best choice:

- Made from renewable biomass sources, not fossil-fuels like some other biodegradable or oxo-degradable plastics, reducing carbon output.

- Is compostable and home-compostable — a legitimate and encouraged recycling solution.

- Will biodegrade in landfill, curbing the accumulation of non-biodegradable plastic waste and breaking down into organic matter.

- Stimulates demand for an industrial composting facility, a solution for a greener future.

Biofilm is an alternative to traditional low-density polyethylene (LDPE) #4 plastic film, which currently is not accepted by local councils for recycling in Australia and has no legitimate facility available to be processed for recycling [1].

Not only do traditional petroleum-based plastics emit copious amounts of greenhouse gases when produced using fossil fuels, but plastic waste accumulates at an alarming rate largely due to its inability to biodegrade, remaining in the environment for hundreds of years. It eventually degrades, leaching into our soils and polluting our oceans with microplastics. With the continuation of the current plastic production rates and waste accumulation trends, landfills and environments such as soils and oceans will roughly accumulate about 12,000 MT of plastic waste by 2050 [2].

To understand the myriad of bioplastic options out there, we need to demystify some of the confusion surrounding them and educate around how to uniquely treat them for the best environmental outcomes.

What are bioplastics?

With so many ‘bio’ terms being thrown around, it’s easy to get mixed up with what they actually mean. Here are some definitions to help clarify things.

A bioplastic can be defined as a polymer that is manufactured into a commercial product from a natural source or renewable resource. Bioplastics refer to either biobased or biodegradable plastics [2].

Biobased plastics are derived from renewable, biomass sources such as cornstarch, sugar cane, vegetable fats and oils, sawdust, wood chips, straw and other raw materials. Unlike traditional plastic, they exclude fossil-based sources. Biobased plastics can be, but aren’t necessarily, biodegradable [3].

Biodegradable plastics can be made from fossil-based materials or biomass sources and will biodegrade under certain conditions at the end of their life, or when correctly disposed of. This relatively small subset of bioplastics can be converted into water, carbon dioxide (CO2) and bio-mass over time with the help of micro-organisms such as microbes and fungi [3].

Oxo-degradable plastics often falsely marketed as biodegradable, oxo-degradable plastics are petroleum-based products that contain additives stimulating the product to break down into tiny fragments (micro-plastics), which do not decompose completely and pollute the environment [5].

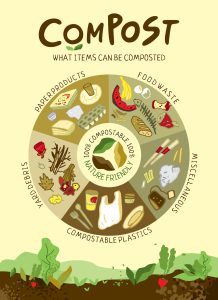

Compostable plastics is a subset of biodegradable plastics, while home-compostable plastics is a further subset still. Not all biodegradable plastics are compostable, and not all compostable plastics are home-compostable [4].

Biobased biodegradable plastics (BBP) are the overlap in the Ven diagram of biobased and biodegradable plastics. BBP can offer the amplified benefits of both decoupling from fossil fuels — thus offering a possible reduction in greenhouse gas emissions and relying on renewable resources — and having potential to biodegrade at the end of its life, reducing the masses of plastic accumulating in landfills and littering our oceans [4].

BioPBS™ is an example of a BBP — derived from biomass sources and biodegradable.

Under what conditions will biodegradable plastics biodegrade?

Nearly every material will biodegrade, with enough time, so claiming plastic is biodegradable without specifying the required conditions can be extremely misleading. The length of the biodegradation process is highly dependent on environmental conditions including oxygen levels, humidity and temperature, and on the mechanical impacts — mixing, vibration [5].

The current biodegradable and compostable plastics on the market today are not suitable for disposal in an open environment. Most industrial composting facilities focus on food scraps and either won’t accept biodegradable packaging or will screen it out for fear or it interfering with their systems. This means most biodegradable plastic currently ends up in landfill [6].

In general, biodegradable plastics can degrade under anaerobic (in the absence of oxygen) conditions in landfills, but in a proper composting facility, or if home-compostable, can be converted into compost and recycled [6].

While better systems for industrial composting are crucial for large-scale solutions, as individuals we can do our part now by home-composting where possible.

Can I home compost BioPBS™?

Using advanced technology from Mitsubishi Chemical Corporation, BioPBS™ is both bio-based, biodegradable and home-compostable.

Studies have shown that while the most favourable degradation environment for BioPBS™ products is compost (degrading after four to six weeks), even soil will produce the same results over the course of several months [6].

You’ll find plenty of information online about how to kick-start your home composting system, but here are some basics to get you started:

- Choose a shady site outside so worms and microbes have the best chance of survival.

- If possible, choose, a spot close to the kitchen for convenient disposal of scraps.

- Dig the bin into the ground at least 10cm to deter unwanted pests.

- Add a layer of twigs, egg cartons and/or dry leaves to assist with aeration.

- Add activators such as comfrey and yarrow, animal manures (not pet poo), compost from an old heap, or blood and bone.

- Lightly spray with water.

Make sure two thirds of the contents are kitchen scrap to one third carbon ingredients. The more diverse the better. When your bin is one third full, turn your compost and repeat every couple of weeks for aeration.

How should I NOT dispose of BioPBS™?

Avoid recycling

Biodegradable and biobased plastics should not be disposed of through traditional recycling streams as their chemical composition and degradation properties differ to conventional plastics. Mixing them can disrupt the recycling process of traditional plastics.

Avoid FOGO

Although compostable BioPBS™ should not be disposed of in your council FOGO bin. Councils do not currently recognise compostable plastics other than authorised compostable bags so it may disrupt their systems.

Is BioPBS™ the same as other bioplastics?

No. Many bioplastics are produced using petroleum-based plastics, requiring non-renewable and carbon-emitting fossil-fuels. BioPBS™ is made using renewable, biomass sources such as sugarcane cassava and corn.

Not all bioplastics are biodegradable or, better still, compostable and home-compostable. BioPBS™ is compostable into biomass, carbon dioxide and water; meaning it’s energy can be recycled into compost. Using advanced technology from Mitsubishi Chemical Corporation, BioPBS™ is also home-compostable, so individuals have the power to start the recycling process now while we wait for industrial composting facilities to catch-up, for the ultimate wide-scale solution.

References:

[1] Crowe, J. LDPE Recycling – Can You Recycle Type 4 Plastics? Waster. Retrieved August 20, 2023, from https://waster.com.au/ldpe-recycling/

[2] Al-Khairy, D., Fu, W., Alzahmi, A. S., Twizere, C., Amin, S. A., Salehi-Ashtiani, K., & Mystikou, A. (2022). Closing the Gap between Bio-Based and Petroleum-Based Plastic through Bioengineering. Microorganisms, 10. https://doi.org/10.3390/microorganisms10122320

[3] European Commission (n.d.). Biobased, biodegradable and compostable plastics. Energy, Climate Change, Environment. Retrieved August 20, 2023, from https://environment.ec.europa.eu/topics/plastics/biobased-biodegradable-and-compostable-plastics_en

[4] European Commission, Directorate-General for Environment, (2022). Biobased plastic: sustainable sourcing and content : final report, Publications Office of the European Union. https://data.europa.eu/doi/10.2779/668096

[5] Transition Australia (n.d.). Biodegradable Plastics Explained. Retrieved August 20, 2023, from https://transitionaustralia.net/biodegradable-plastics/

[6] S Jeremic, J. Milovanovic, M. Mojicevic, S. Skaro Bogojevic, J. Nikodinovic-Runic, J. Serb. Chem. Soc. (2020) https://doi.org/10.2298/JSC200720051J

Editor at Vanguard Publishing.

Style: Edgy & Eclectic

Interest: Storytelling, Content Direction, Branding